|

|

HOME | CONTACT US | FIRE RETARDANT COATINGS | TESTING

Vacuum Pressure Impregnated - Kiln Dried After Treatment (KDAT)

Flameproof Plywood, Flameproof Lumber, Fireproof Timbers, Shake Shingles, Architectural Millwork, Specialty Treatments |

| VACUUM- PRESSURE IMPREGNATION |

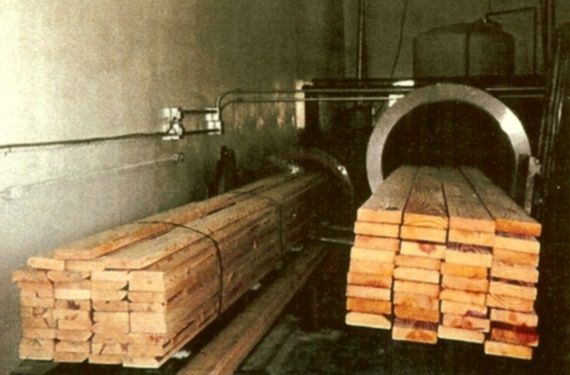

Lumber, plywood or timber is loaded into a treatment cylinder. The door is sealed and a vacuum is applied. During this stage, most of the moisture and air is removed from the wood cells. The vacuum in the cylinder causes the cylinder to fill with Flame Safe’s proprietary fire retardant. Pressure is raised in the cylinder forcing the fire retardant solution into the wood. The pressure and time varies depending on the species of the wood, the commodity being treated, the cross-sectional area, and the amount of the fire retardant solution to be impregnated into the wood. The pressure in the cylinder forces the remaining fire retardant solution to flow back into a holding tank. Another vacuum is applied, removing the excess fire retardant solution from the wood. The lumber, plywood or timber is loaded onto trams that service a gas fired forced air kiln.

|

KILN-DRYING

Heated air is used to extract moisture from wood. |

A gas fired forced air convection system removes most of the moisture from the wood after treatment. The moisture laden air is dehumidified. The drying rate is monitored to prevent cracking in the lumber. Lumber is kiln dried to a moisture content not to exceed 19%. Plywood is kiln dried to a moisture content not to exceed 15%. Finished moldings and trim is kiln dried to a maximum moisture content of 6 to 12% depending on the species and specific use. Pitch in the wood is crystallized permitting interior and exterior finishes to be easily applied. When kiln dried, Flame Safe treated wood becomes lighter and stronger, maximizing it’s structural uses.

|

SPECIFICATIONS

All Flame Safe’s treated lumber, plywood and timber shall be vacuum-pressure impregnated to comply with the ASTM E-84 standard (UL723 and the NFPA 255) and shall have a flame spread rating of 25 or less.

All Flame Safe’s licensed manufacturers are monitored with Fire Prevention Technologies’ Follow-Up Service (FPT-FUS). FPT-FUS requires compliance to the ASTM E-84 standard or ASTM D-3806 equivalency for Class A Type 1 (Surface Burning Characteristics of Building Materials).

Each piece of treated lumber, plywood, timber or architectural millwork shall bear a Flame Safe tradename and/or it’s “Firebuster ™” trademark.

FLAME SAFE WOOD PRODUCTS MEET THE TESTS |

Flamespread less than 25

in accordance with

ASTM E-84 - NFPA 255 - UL723 |

Conforms to

AWPA STANDARDS

C-20 for lumber and C-27 for plywood |

|

PROPERTIES OF FLAME SAFE TREATED WOOD |

Permanence

Flame Safe treated wood is a permanent guard against the spread of fire.

Strength

Flame Safe’s aqueous based resin treatment and kiln-drying process strengthens the wood

Hygroscopicity

Flame Safe treated wood is no more hygroscopic than untreated wood of any given species.

Corrosion

Flame Safe treated wood does not demonstrate any greater corrosion rate than untreated wood on metal fasteners or hardware.

Decorating and Finishing

Flame Safe treated wood surfaces can be stained or painted with ordinary preparation, however avoid using lacquer based stains or varnishes.

Field Cuts

Flame Safe treated wood allows the user to re-surface, mill, or rip lumber or plywood without effecting the fire rating

Versatility

Flame Safe treated wood is compatible with most waterborne preservative treatments for lumber, plywood and timber for exterior and in ground use.

ADVANTAGES OF FLAME SAFE VACUUM-PRESSURE TREATED WOOD

| *Reduces flamespread to less than 25 *Water-based wood preservative *Odorless * Environmentally friendly *Resistant to insects and rodents *Termite resistant |

*Reduces smoke generation *Requires no special cutting tools *Will not harm plants or animals *Fungus and mold inhibitor *Contains no sulfates |

Flame Safe’s treated wood is a low cost, effective building material for homes, apartments, manufactured housing, hotels, restaurants, outdoor decks, balconies, docks, commercial, industrial, and institutional buildings, for interior and exterior use |

|

| |

Abilene, Dallas, Fort Worth, San Antonio, Austin, Houston, Corpus Christi, Oklahoma City, Tulsa, Kansas City, St. Louis, Texas, DFW, Odessa

HOME | CONTACT US | FIRE RETARDANT COATINGS | TESTING

The information contained herein is the property of fire prevention technologies d/b/a Flame Safe Chemical Corporation and Flame Safe Wood Products, Inc . copyright 1990 Revised 8/20/2009 Revised 2012, revised 2015

|

|